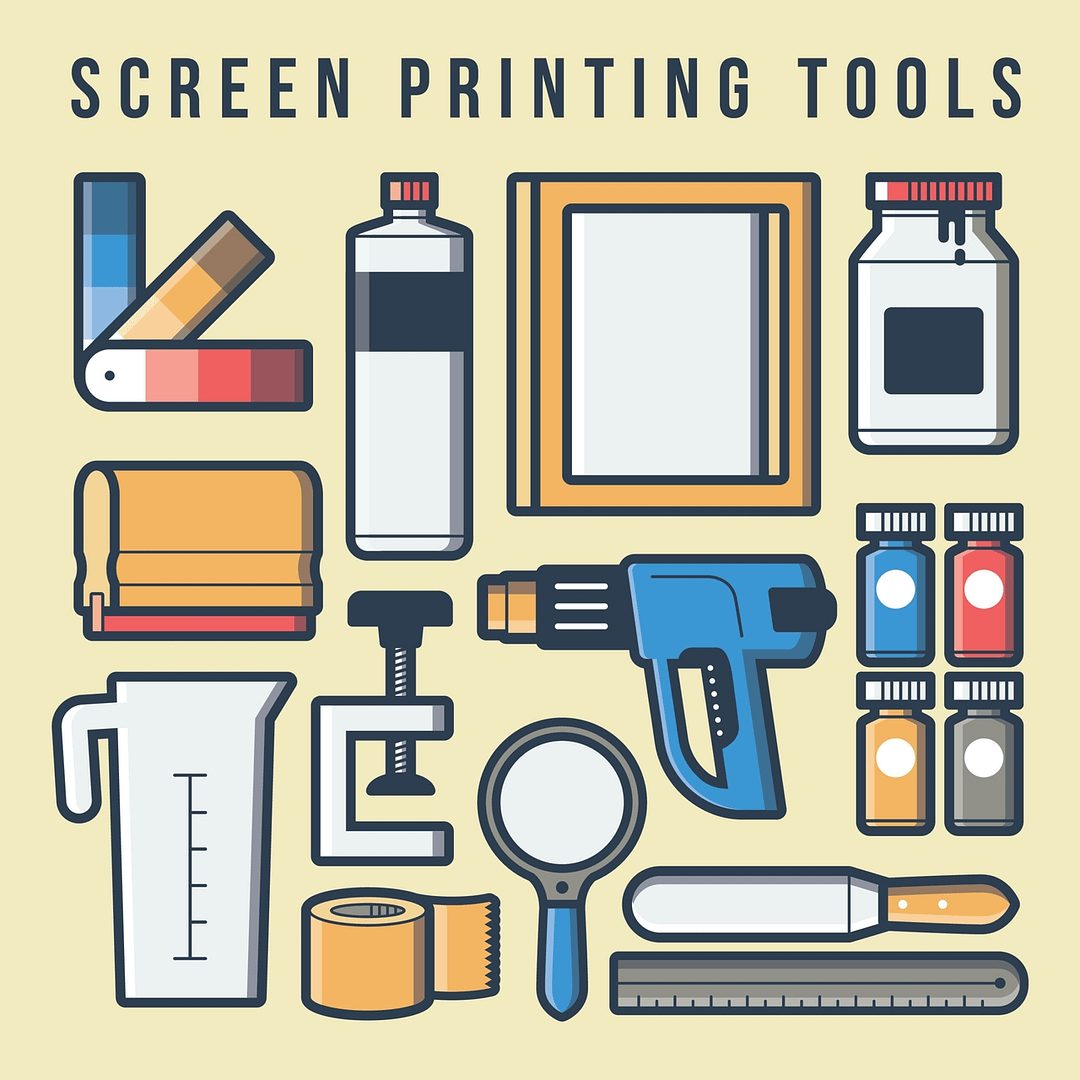

Screen printing is a popular method of printing that has been used for centuries to create high-quality and durable prints on various surfaces. Whether you’re a professional screen printer or a hobbyist, having the right tools is essential for achieving excellent results. In this article, we will explore the essential tools that every screen printer should have to ensure success in their printing endeavors.

Introduction to screen printing

Screen printing, also known as silk screening, is a technique that involves transferring ink onto a substrate through a mesh screen. The screen acts as a stencil, allowing the ink to pass through only in specific areas, creating the desired design or image. It is widely used in the textile industry for printing on t-shirts, hoodies, and other apparel items. Additionally, screen printing is also used for printing posters, signage, labels, and even circuit boards.

Importance of having the right tools for screen printing

Having the right tools is crucial for achieving accurate and professional-looking prints. The quality of your tools directly impacts the outcome of your prints, and using subpar or inadequate equipment can result in smudged, uneven, or inconsistent prints. By investing in the right tools, you can enhance your printing efficiency, improve print quality, and save time and resources in the long run.

Basic tools for screen printing

Screen Printing Frame

The screen printing frame is the foundation of the screen printing process. It holds the mesh screen tightly, ensuring that it remains in place during printing. The frame should be sturdy and flat to prevent any distortion or sagging that could affect the quality of the print.

Squeegee

A squeegee is a handheld tool used to push the ink through the mesh screen onto the substrate. It is essential to choose a squeegee with the appropriate hardness and size for your specific printing needs. Hardness determines how much pressure is applied to the ink, while the size of the squeegee affects the coverage area.

Emulsion and Scoop Coater

Emulsion is a light-sensitive liquid that is applied to the mesh screen before exposing it to UV light. It hardens when exposed to light, creating the stencil that allows the ink to pass through. A scoop coater is used to evenly distribute the emulsion on the screen, ensuring consistent stencil quality.

Screen Printing Ink

Choosing the right ink is crucial for achieving vibrant and durable prints. Screen printing inks come in various types, such as water-based, plastisol, and discharge inks. Each type has its advantages and is suitable for different substrates. Consider factors such as color opacity, washability, and environmental impact when selecting the ink.

Exposure Unit

An exposure unit is used to expose the emulsion-coated screen to UV light

to cure or harden the emulsion. It consists of UV light bulbs or LEDs and a vacuum mechanism to ensure proper contact between the artwork and the screen. An exposure unit is essential for achieving sharp and detailed prints.

Heat Gun or Flash Dryer

A heat gun or flash dryer is used to quickly dry the ink after printing each color layer. It helps prevent smudging or bleeding of colors and allows for faster production. A heat gun is handheld and provides targeted heat, while a flash dryer is a larger unit that applies heat evenly to the entire print area.

Cleaning Supplies

Keeping your equipment clean is essential for maintaining print quality and prolonging the life of your tools. Cleaning supplies such as screen degreaser, screen wash, and emulsion remover help remove ink and emulsion residue from the screens, frames, and squeegees.

Tape and Masking Materials

Tape and masking materials are used to block off areas of the screen that should not receive ink during printing. Masking tape, screen blockout, and screen tape are commonly used to create clean and precise prints, especially when working with multiple colors or intricate designs.

Advanced tools for screen printing

While the basic tools mentioned above are essential for screen printing, advanced tools can further enhance your productivity and capabilities. These tools are often used by professional screen printers or those handling large-scale production.

Conveyor Dryer

A conveyor dryer is a machine that uses heat and a moving belt to cure the ink on printed garments or other substrates. It provides consistent heat and airflow, ensuring thorough curing and faster production times compared to using a heat gun or flash dryer.

Automatic Press

An automatic press is a high-end screen printing machine that automates the printing process. It allows for precise registration, faster printing speeds, and reduced manual labor. Automatic presses are ideal for large-volume production and complex designs.

Registration System

A registration system helps align multiple colors accurately during the printing process. It typically consists of registration marks and adjustable micro-registration knobs on the screen printing press. This tool ensures that each color layer aligns perfectly, resulting in clean and crisp prints.

Spot Cleaning Gun

A spot cleaning gun is used to remove unwanted ink or stains from the screen or garments. It sprays a cleaning solvent, which dissolves the ink, making it easier to wipe away. Spot cleaning guns are handy for touch-ups and ensuring a clean printing surface.

Pressure Washer

A pressure washer is useful for deep-cleaning screens, frames, and equipment. It uses high-pressure water to remove stubborn ink, emulsion, and debris from the mesh screen. Regularly cleaning screens with a pressure washer helps maintain optimal printing conditions.

Drying Cabinet

A drying cabinet is an enclosed space with controlled temperature and airflow designed to accelerate the drying process of printed garments. It ensures thorough curing of the ink and reduces the risk of smudging or ink transfer during storage or transportation.

UV Exposure Unit

A UV exposure unit is an advanced version of the standard exposure unit. It uses UV LED lights instead of traditional UV bulbs, providing faster exposure times and more precise stencil detail. UV exposure units are ideal for intricate designs or fine lines.

Choosing the right screen printing tools for your needs

When selecting screen printing tools, consider factors such as your budget, production volume, printing goals, and the types of substrates you work with. Start with the essential basic tools and gradually invest in advanced equipment as your business grows. It’s important to research different brands, read customer reviews, and seek recommendations from experienced screen printers to ensure you choose reliable and high-quality tools.

Conclusion

Having the right tools is paramount for achieving success in screen printing. Whether you’re a beginner or an experienced professional, investing in high-quality equipment will significantly enhance your print quality, efficiency, and overall printing experience. By equipping yourself with the essential tools like screen frames, squeegees, and inks, as well as considering advanced options such as conveyor dryers and automatic presses, you’ll be well-equipped to create outstanding prints on various substrates. Remember to choose tools that align with your specific needs, budget, and production volume. With the right tools in your arsenal, you’ll be able to unleash your creativity and take your screen printing endeavors to new heights. If you are inspired to start screen printing read more here.